Preparing a shrimp pond for successful cultivation is a crucial step, whether you’re utilizing an existing pond or creating a new one. The cleanliness and readiness of the pond are paramount to ensure optimal conditions for shrimp growth. The preparation process may differ based on the soil type in the shrimp farm. In this guide, we’ll explore important considerations for pond preparation to help you achieve a thriving shrimp farming environment.

The soil type in the shrimp farm

§ Clay Soil:

Once the shrimp farm pond has been emptied of water, the clay sediment will accumulate at the center. Give it time to air dry, and subsequently, eliminate it from the shrimp pond.

§ Clay Mixed with Sand:

For this particular soil type within your shrimp farm, it’s essential to plow and till the pond’s bottom, retaining the clay content. Afterward, allow the pond to dry and make necessary adjustments to its level. Finally, compact the soil to prepare it effectively.

§ Sandy Soil:

Excavate the shrimp pond until you reach the layer of dark-colored soil. Allow the pond to desiccate until the soil loses its darkness. Modify the pond’s elevation and consolidate the soil. Alternatively, employ a technique to introduce clay to eliminate the dark layer at the bottom and retain the clay within the shrimp farm pond.

§ Acidic Soil:

Avoid of tilling the soil in your pond, as it may draw acidic compounds from the lower soil layers. Let the pond dry out, followed by refilling it with water. Use lime-based materials to balance the pH level.

Shrimp Farming in PE Ponds

A favored choice among shrimp farmers is the utilization of PE lining within their shrimp ponds. This PE lining comes in two varieties: a thinner version measuring 0.15 mm and a thicker option at 0.3 mm. When adequately maintained, the thinner lining can endure for about three years.

Benefits of PE Lining in Shrimp Farms

– Mitigates soil erosion in the pond.

– Minimizes the likelihood of pond seepage within your shrimp farm.

– Prevent iron corrosion.

– Enhances water management capabilities.

– Preserves the cleanliness of shrimp feed, preventing soil contact.

– Diminishes the buildup of organic matter at the pond’s base within your pond

Differences Between PE-Lined and Non-PE-Lined Ponds in Shrimp Farms

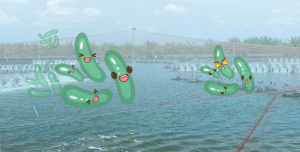

PE-lined ponds in your shrimp farm tend to have greener water due to the absence of suspended clay particles that hinder plant photosynthesis. They also support faster phytoplankton growth, benefiting shrimp nutrition. In contrast, non-PE-lined ponds in your shrimp farm may have cloudy water initially, which could delay phytoplankton growth.

After some time, non-PE-lined ponds in your shrimp farm may accumulate clay particles, making the water cloudy. Shrimp in your shrimp farm may become stressed, affecting their feeding and growth. In contrast, PE-lined ponds in your shrimp farm don’t face this issue.

Using Lime Materials in Your Shrimp Farm:

Lime materials are essential for aquacultural pond preparation and water quality management in your shrimp farm. There are three main types of lime materials:

1. Hydrated Lime (Calcium Hydroxide)

In the oxide group, we have calcium oxide (CaO) and magnesium oxide (MgO). The one most commonly used is calcium oxide, also known as quicklime. Quicklime possesses properties that aid in addressing acidic soil conditions, leading to the fastest increase in pH levels. When quicklime comes into contact with water, it generates heat, raising the water temperature

2. Calcium Oxide

Lime in the hydroxide group includes calcium hydroxide (Ca(OH)₂) and magnesium hydroxide (Mg(OH)₂), also known as hydrated lime. These types of lime have properties that cause pH levels to increase more rapidly than carbonate-based lime but less so than oxide-based lime. They have a milder effect on carbonate alkalinity. When they come into contact with water, they generate heat, raising the water temperature.

3. Marl or Limestone (Calcium Carbonate):

Carbonate Group Lime encompasses various natural lime materials, such as limestone (CaCO₃), dolomitic limestone (CaMg(CO₃)), clamshells, and marl. These materials offer a gradual yet lasting adjustment to pH levels in aquatic environments. Unlike their high-temperature processed counterparts, they are sourced naturally, maintaining their integrity and safety. Carbonate group lime effectively boosts carbonate alkalinity in water without causing temperature spikes upon contact. This makes it a reliable choice for ensuring the well-being of shrimp.

Preparing Water Before Start Shrimp cultivation:

Pond Preparation

1. Draw water into the shrimp pond, filtering it thoroughly through four layers of fine fabric filter bags. Remove impurities and suspended solids.

2. Eliminate impurities by using 60% chlorine at a rate of 300 kg per hectare. Dissolve the chlorine in a container, stirring until it is completely dissolved. Then, evenly distribute it throughout the pond during the evening when the pH level is between 7.3 and 7.8. Alternatively, you can use 8-10 kg of trichlorfon per hectare, dissolved in a similar manner to chlorine. Apply trichlorfon in the afternoon when the pH is 7.8 or higher.

3. Mix the treated water thoroughly in the pond to ensure optimal effectiveness. It is advisable to add the treatment during the evening when the pH level is within the recommended range.

4. Afterward, seed the pond with microorganisms by using tea waste (20-30 kg per hectare) or powdered tea waste (100 kg per hectare) to eliminate substances such as sulfides, protozoa, and snail eggs. Use tea waste to tackle issues related to sulfide compounds, which are harmful to shrimp.

Water Coloring

1. When it comes to applying chemical fertilizers, do so after completing disease control measures and pond drying. Apply 10 kg per hectare of chemical fertilizers every three days until the water turns green. Once the water is green, you can proceed with stocking shrimp.

2. To prevent shrimp from being startled and stressed due to sudden exposure to bright light, especially when the water is clear, consider using artificial water coloring. Apply it one day before releasing the shrimp. This shading helps prevent birds and predators from spotting and consuming the shrimp. For shrimp species like Macrobrachium rosenbergii, Macrobrachium lanchesteri, and white shrimp that are raised in shallow water, direct sunlight during midday can significantly increase the temperature at the pond bottom. Therefore, adding a green or blue-green tint to the water is recommended.